Envis Centre, Ministry of Environment & Forest, Govt. of India

Printed Date: Saturday, December 27, 2025

Parascole West Colliery on 06.07.1999

Parascole West Colliery Air Blast Accident

| Date of the Accident |

- 6.7.1999 |

| Owner |

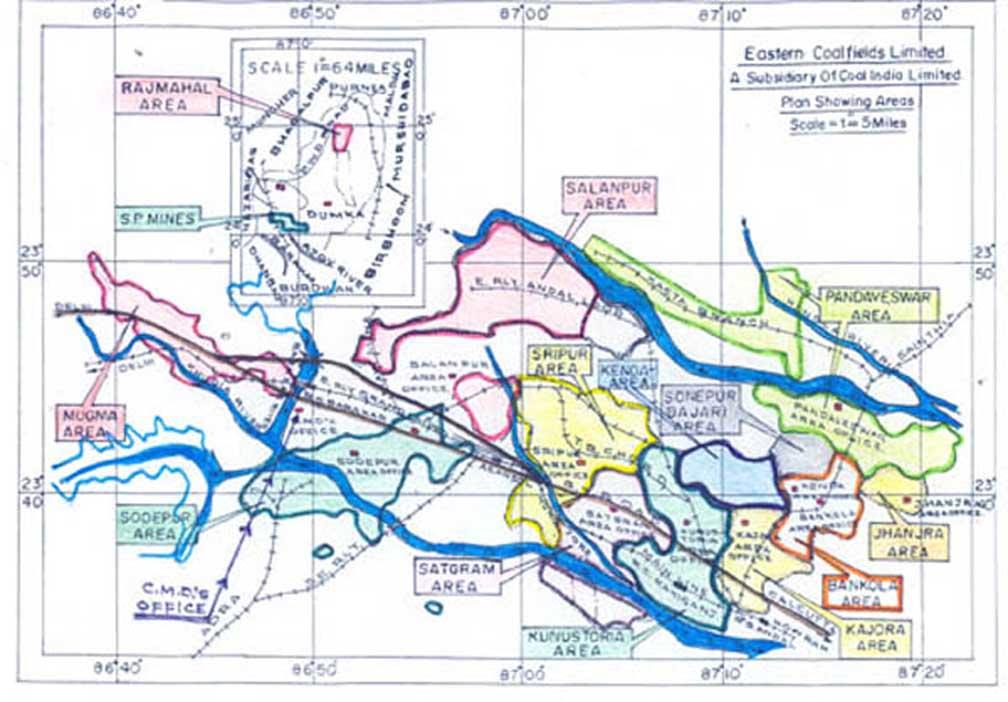

- Eastern Coalfields Ltd. |

| Number of persons killed |

- 5 |

| Place |

- Kajora Area, District: Barddhaman, West Bengal |

Parascole West Colliery

The accident occurred in Panel 23-I in Jambad seam top and bottom sections worked through No.1 and No.6 Pits. Jambad seam, about 12.6 m thick and dipping at about 1 in 16, has been developed in two sections leaving a parting of 5 m between the sections. The seam is overlain by 50 m to 55 m thick massive sandstone which is very difficult to cave. Hence the seam on the dip side of the property was depillared in both sections in conjunction with hydraulic sand stowing except in one panel where the top section was caved. In this caving panel, an air-blast had occurred in 1987 and since then extraction of the seam by caving method was stopped.

Meanwhile, CMRI had developed a method known as yield pillar technique to extract Jambad seam in adjoining Parascole East Colliery where 5 panels were extracted successfully by caving without any incidence of air-blast. Therefore, the management requested CMRI to study the feasibility of extracting Jambad seam at Parascole West Colliery in similar manner by caving method. CMRI designed the panels and DGMS granted permission initially to extract two panels as per the recommendations of CMRI. After successful completion of extraction in two panels, permission was granted for more panels and by 31.12.1998, a total of 11 panels had been extracted without any untoward incident.

Permission for extraction in Panel No.23- I was granted on 11.2.1999 with the following conditions:

- Depillaring operations shall be conducted with proper instrumentation and monitoring. At least two instruments (strain bar) shall be provided in each yield pillar and barrier pillar to monitor roof behaviour. Proper record of readings of instruments shall be maintained. The yield pillars shall not be reduced or extracted except the pillars in the top section which may be split along the level and the rest of the pillar shall be left as it is.

- As suggested by CMRI, after a yield .of 5.5 mm compression in the Yield pillar, all workers shall be withdrawn from the area to a safe place. Work in the area shall be resumed only after the area has been declared safe by the manager.

- At least 15 convergence recorders shall be installed in the vicinity of pillars under extraction to obtain indication of an impending roof fall as recommended in circular No.2 of 1988. Mock rehearsals shall be held periodically to familiarize workers with the precautions to be taken when an air-blast is apprehended.

Pillar extraction in Panel 23-I

The panel was 130 m x 78 m in size. Workings in the two sections were reasonably superimposed. Isolation stoppings provided in the two sections were also superimposed. Height of extraction in each section was 4.8 m, leaving a parting of about 3.0 m between the sections. Extraction in the panel commenced on 12.1.1999. The first local fall occurred on 25th March and subsequent falls occurred on 30th April, 24th June and 30th June. During the local falls, about 1.5 m to 2.0 m thick shale roof fell down and the parting between the sections also collapsed. By the end of the third shift on 5th July, eight pillars (26 m x 26 m) had been extracted and five pillars remained to be extracted. About 78 m x 78 m of roof in the goaf was standing. The adjoining worked out Panel No. 23-F on the rise side had been sealed off, but the goaf was standing.

The accident:

No strata movement in the goaf had been observed in the panel during the third shift of 5.7.1999. In the morning shift of 6.7.1999, the top and bottom sections had been inspected by the mining sirdars of the two sections, the senior overman, assistant manager and the manager himself and upto about 10.40 a.m. there was no indication of any strata movement or weighting on the supports or on pillar sides either in the top section or bottom section. At about 10.40 a.m., a dresser, who was dressing the roof in the top section, felt the effect of impending fall of roof in the goaf and he immediately informed the mining sirdar. At the same time, the manager, the overman and mining sirdar, who were standing together in the bottom section, felt that the air was being sucked into the goaf. The mining sirdar blew his whistle to warn the workers and he himself lay down on the floor. Suddenly the overhanging roof in the goaf came down causing an air-blast. The fall was so sudden that the mining sirdar of the top section did not get time to warn the workers.

Subsequent inspection and inquiry revealed that the main roof in the goaf over an area of 75 m x 75 m in the working panel and about 130 m x 78 m in the adjoining sealed off panel had fallen suddenly without any prior indication, causing an air-blast which resulted in the death of two persons on the spot and serious bodily injuries to six persons of whom two died on the same day and one the following day in the hospital. Twenty others received reportable or minor injuries.

Cause of the accident:

The panel was being worked in grass violation of the conditions stipulated in the depillaring permission. The management had failed to install instruments to monitor the compression of the yield pillar and barrier pillars. No convergence recorders had been installed in the vicinity of the pillars under extract in to obtain indication of an impending roof fall. If these instruments had been installed and regular readings were taken as stipulated in the permission letter, the officials would have got prior warning of the fall and could have withdrawn the workers to safe places. Therefore the entire responsibility for the accident lay with the management.

[High Powered Committee was constituted by the Ministry of Coal, Government of India vide Office Memorandum No. 22022/45/99-CRC dated 29.07.99 to go into details of the accident at Parascole (West) colliery, High Powered Committee recommended action against four officials of ECL. DGMS has launched prosecution against officials held responsible in its enquiry.]