You are here :

Home Mahabir Colliery on 13.11.1989

|

Last Updated:: 02/06/2015

Mahabir Colliery on 13.11.1989

Mahabir Colliery

| Date of the Accident |

- 13.11.1989 |

| Number of persons killed |

- 6 |

| Owner |

- Eastern Coalfields Ltd. |

| Place |

- Raniganj Coalfield. |

[For the first time in the history of mining in India, 65 miners trapped belowground could be rescued through a large diameter borehole drilled from the surface.]

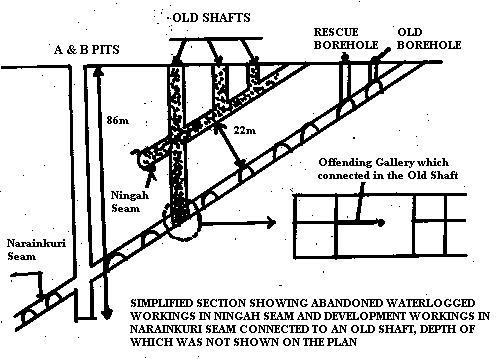

The colliery was working Narainkuri seam through two shafts, A and B about 86 m deep. The seam had been extensively developed and at the time of the accident, development was going on towards the rise-most area of the mine. The overlying Ningah seam (parting 22 m) had been worked and abandoned a long time back and was full of water. On 13.11.1989 at about 4 a.m., a heading in Narainkuri seam punctured into an abandoned shaft (Pit No.34, which was not shown on the plan of Narainkuri seam) through which water of Ningah seam started rushing into Narainkuri seam. Heavy flow was reported for about 45 minutes. There were 232 persons employed belowground in the night shift of whom 161, working in the vicinity of the shafts, could come out. 71 could not reach the shafts as the roadways leading to the shafts had got flooded. In a short time, both the shafts got flooded upto a height of 12 m Above the pit-bottom. Fortunately there was a telephone connection between the underground workings (where the miners were trapped) and the surface and it was learnt over this telephone that 65 miners had taken shelter in the rise part of the workings. Thus 6 miners could not be accounted for.

It was decided to install as many submersible pumps in the two shafts as possible to dewater the mine and at the same time to drill a large diameter hole in the rise-most area to establish communication with the trapped miners.

Pumping: The first submersible pump started working at 1.45 p.m. on 13.11.1989 and more pumps were installed as they came in so that by 3.30 p.m. on 18.11.1989 eleven pumps with a total capacity of about 1750 m3/hr were working in the two shafts. But the actual quantity delivered by the pumps was found to be only about 1150 m3/hr, representing a dewatering rate of 25000 m3/day. Surprisingly enough, the lowering of the water level in the pits corresponded to a dewatering rate of only about 5000 m3/day. Obviously, there must have been heavy recirculation of the water. It was reported from the underground workings that heavy inflow was still continuing through shaft on 34. It was therefore concluded that the pumped out water was finding its way back into the old workings of Ningah seam through surface cracks. To stop the flow through Pit No.34, this pit (30 m deep) was reactivated by erecting a temporary headgear and winder and this shaft was later plugged on 20.11.1989 to stop the flow from Ningah to Narainkuri seam. After this was done, the level of water in shafts A and B started receding at a faster rate.

Drilling of communication borehole: It was learnt from the mine officials that two exploration boreholes had been drilled in the past to prove the depth and thickness of the coal seam and one of these boreholes had subsequently been met with in one of the underground galleries. This borehole was found out and a drilling rig was set up at the site. Drilling of a 255 mm (10″) dia. hole started on 13.11.1989 at 9.30 p.m. and after passing through 8 m of alluvium, the borehole was lined with 200 mm (8″) casing. Thereafter the borehole continued with 200 mm dia. upto 15.65 m through semi-hard but sticky strata which took a considerable time to pass through. A second casing of 150 mm (6″) dia. was fitted in this portion of the borehole and the next stage continued with 150 mm (6″) dia through medium-hard rocks. At 3.30 a.m. on 14.11.1989 (that is in 6 hrs. of drilling time) the hole touched the gallery at a depth of 27.80 m. A lighted torch was lowered through this hole and the trapped miners were told over the phone to come to the borehole site. Thus direct link with the trapped miners was firmly established at 4 a.m. on 14.11.1989 (that is, in exactly 24 hours from the time of flooding). Torches, food, drinking water, medicines, etc. were lowered through this borehole.

Drilling of rescue borehole: A second borehole of 200 mm (8″) diameter was drilled close to the first borehole. Drilling started on 14.11.1989 at 9.30 a.m. and the hole punctured the underground gallery at 11.30 a.m. The hole was enlarged to 21.5″ in four stages (to 12″, 15″, 18″ and finally to 21.5″). The hole of 21.5″ dia was completed at 1.30 p.m. on 15.11.1989. It was feared that the alluvial portion of the borehole might collapse and choke the borehole. Therefore the top 11 m was further enlarged to 28.5″ diameter and lined with 24″ dia. steel ventilation ducting.

While drilling was going on, a steel capsule of 17″ inside diameter and 2.5m height had been fabricated. This capsule was lowered into the borehole using a derrick and 10t hand winch. After a few trial runs up and down the hole, rescue of men was started at 2.30 a.m. on 16.11.1989. By the time six men were taken out, it was observed that each cycle was taking about 15 minutes. To expedite the operation, a 12 tonne crane was put into service for lowering and raising the capsule and this reduced the cycle time to just 3 minutes. All the 65 persons were taken out from the mine by 9 a.m. on 16.11.1989.

The hero of the rescue operation was Shri J. S. Gill, Addl. Chief Mining Engineer, who risked his own life and went down the borehole in the capsule and organized orderly evacuation of the trapped miners. Initially this move was opposed by top officers, including the chairman of the CIL, as he was reluctant to risk the life of a senior officer. As the capsule landed in the muddy and watery patch, he opened the latch come out, picked up the first person he saw, put him in the capsule and gave the signal for the capsule to be hoisted. This gave him 20 minutes to organize the remaining 64 trapped miners. Over 20,000 people had assembled to witness the tension-charged rescue operation. It had taken about 6 hours to bring up the 65 miners one-by-one and last of all when Shri Gill emerged from the capsule, people went mad with emotional outburst. They lifted him on their shoulders and heaped him with garlands. The scene cannot be described in words; it is best left to the imagination of the reader to re-create it in his own mind, and thus ended a glorious chapter in the history of Indian mining.

Shri Jaswant Singh Gill was honoured with India’s highest civilian gallantry award Sarvottam Jeevan Raksha Padak (SJRP) for saving the lives of 65 miners, by President of India. Before Shri Gill, No living person had been honoured with this gallantry award. However, many people have received it posthumously. His historic act of bravery on November 16 is celebrated by Coal India Ltd as ‘Rescue Day’.