You are here :

Home Loyabad Colliery on 30.1.1936

|

Last Updated:: 21/07/2015

Loyabad Colliery on 30.1.1936

Loyabad Colliery

| Date of the Accident |

- 25.1.1994 |

| Owner |

- Eastern Coalfields Ltd. |

| Number of persons killed |

- 55 |

| Place |

- Raniganj Coalfield |

On 25.1.1994 at about 3.30 p.m. a fire broke out in the workings of Dobrana seam at New Kenda Colliery. The fire occurred in the main intake airway close to the downcast shaft. Smoke and noxious gases from the fire spread to the working places and caused the death of 55 persons. This has been the worst fire disaster of this century in Indian mines.

Two seams, namely, Kenda (8.31 m thick) and Dobrana (5.4 m thick) were being worked through shafts. The upper Kenda seam had been opened sometime in 1907 and had been developed extensively. At the time of the accident, it was being depillared in conjunction with hydraulic sand-stowing. The Dobrana seam, lying 55 m below Kenda seam, was started in the year 1962 and had been extensively developed through Pit nos. 2 and 3. The area on the rise side of the west shaft-levels had been depillared mostly by caving more than 10 years ago. The rise-side goaves were isolated by fire-stoppings with provision for water drainage where necessary. At the time of the accident, the seam was being developed on the south-west side of Pit nos. 2 and 3.

The Dobrana seam has been classified as a gassy seam of the second degree but no occurrence of gas had ever been reported. The coal is very cleaty and its crossing point temperature varies between 145°C and 155°C. Although the seam had been extensively depillared with caving in the past 20 years, there had been no case of fire in the seam. The seam is therefore considered only moderately susceptible to spontaneous combustion. However, the Kenda seam at this colliery had several occurrences of heating and fire.

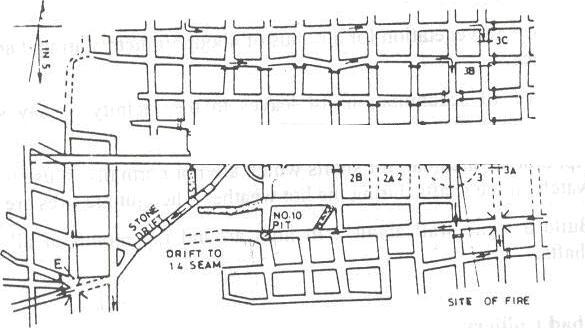

The fire in the ‘zero’ west level of Dobrana seam on 25th January was apparently caused by spontaneous heating of the roof coal although there was no indication of self-heating before the occurrence. The large quantity of air flowing in the roadway might have diluted the symptoms of heating like smoke, stink, CO and heat to innocuous levels. Hot and burning coal appears to have fallen down from the roof and on being exposed to the large quantity of flowing air; it produced smoke and noxious gases profusely. Although normally it was a busy area, nobody was present near the spot where the burning coal fell down and the fire could not be tackled immediately. Water was not available to quench the fire. Pumps in the main sump could not be operated due to a cable fault. Attempts were made to quench the fire by throwing some stone-dust but were not successful. Subsequently Nitrogen was used in both liquid and gaseous form but it failed to extinguish the fire which kept burning like a furnace. Finally the fire area was sealed off in the middle of February enclosing ‘zero’ and 1 west levels. The plan shows the fire seals numbered 1 to 27.

As the fire area had already been sealed, the Court of Enquiry constituted to find out the causes and circumstances of the fire, could not make any progress for quite some time for lack of any direct evidence. After about one and a half year when the fire had died down, the area was reopened and examined by experts. Heavy roof falls were encountered in the sealed off galleries. The fallen mass contained unburnt coal at the bottom with stones on top mixed with coal or coal ash. The stones consisted of shale and sandstone which were subjected to various degrees of heating or burning.

Different parties had attributed the following three reasons for the fire-

- Short circuiting or bursting of electrical equipment of the underground sub-station.

- Fire travelling from the rise-side goaf by breaking open No.8 isolation stopping.

- Spontaneous heating of the roof coal.

All electrical equipment and cables were examined by experts after re-opening of the area. The equipments were found in their respective positions and were in tact. There was no sign of any explosion.

The possibility of fire travelling from the adjoining goaf was ruled out as three witnesses who were standing near the said stopping at the time of the accident had heard a loud sound and seen smoke coming from the eastern side. Moreover, the rescue team which had entered the goaf after breaking No.7 stopping had not found any evidence of fire inside the goaf. In fact they had found in tact wood and coal just below No.7 stopping. The wood and coal showed no sign of burning.

Cause of the fire

The fire was caused by spontaneous heating of roof coal in ‘zero’ west level. Spontaneous heating started in the top 25 cm of the roof coal. Because of the cooling effect of 2800 m3/minute of intake air, the heating could not have started anywhere lower. The 25 cm coal band had shale both above and below and therefore the fire remained confined within the 25 cm coal band. This fire had spread towards the west and north sides, helped by partial crush of the coal and air supply. The fire had a much larger horizontal spread than the usual roof coal fires. This large horizontal spread acted as a bed-separation for the overhanging shale and coal below. To this was added the dead load of the heat-affected shale above. The roof thus gave way before the fire could surface along the ledge of top coal. When this fall occurred at about 3.35 p.m., a large area of burning coal was exposed to a large volume of air resulting in rapid spread of fire.

Part Plan of 15 seam workings at Loyabad Colliery showing the site of fire and the positions of the stoppings built to control the fire

Responsibility

The fire was caused by spontaneous heating at a place where sufficient volume of air was passing through. There was no indication of self-heating. Workers were travelling through the ‘zero’ level all the time. Therefore, the Court held that nobody had defaulted in his duty in preventing or detecting the fire.

Observations

- No telephone communication was in operation between the end of the haulage system and the pit-bottom and pit-top as required by CMR 87(4) (b). Had such communication been available, the workers could have been told to come out through the West side and a good number of lives could have been saved.

- If water had been used initially on the hot mass that fell from the roof, possibly the fire would have been quenched. But there was no arrangement for water supply in the gallery. This was in gross violation of CMR 120(1) (a).

- As the fire had occurred close to the downcast shaft, the fan should have been stopped or reversed promptly. The management would then have got sufficient time to rescue persons working inbye. It appears that nobody was ready to take upon himself the responsibility of this decision. They only tried to fight the fire through small attempts.

- Workers had not been provided with self-rescuers in contravention of CMR-191D. If workmen had been provided with self-rescuers, they would have got at least half-an-hour or more time to escape.

- The rescue plan showed an escape route but this was neither well-marked nor kept clear and secured. The workmen had no idea of this escape route. Another route to No.2 Pit was also available through the eastern side. The workmen could have used this route and saved themselves, but it appears they were not aware of this route either. Twenty six dead bodies in sitting posture were found at a place within 350 m of Pit No.3. Had these persons taken courage to move forward towards Pit No.3, they had a chance of saving themselves. But without doing so, they sat together and probably were conferring on their own fate. Obviously, the workmen were not made aware of the mine layout.

- Large areas belowground in this mine have been developed unsystematically. This is undesirable. The government should frame regulations to ensure systematic development of underground mines.

- Risk of fires in mines has not drawn serious attention of the management. Effective arrangements to deal with the fire immediately are lacking. A comprehensive regulation defining the role of the controlling authority and specifying the emergency response mechanism and method of fire fighting is needed.