You are here :

Home Jamuria Colliery on 08.10.1943

|

Last Updated:: 19/05/2015

Jamuria Colliery on 08.10.1943

Jamuria (7 & 8 Pits) Colliery Air Blast Accident

| Date of the Accident |

- 8.10.1943 |

| Owner |

- Equitable Coal Co. Ltd. |

| Number of persons killed |

- 12 |

| Place |

- Raniganj Coalfield |

Air Blast: Jamuria Colliery Mining Accident on 08.10.1943

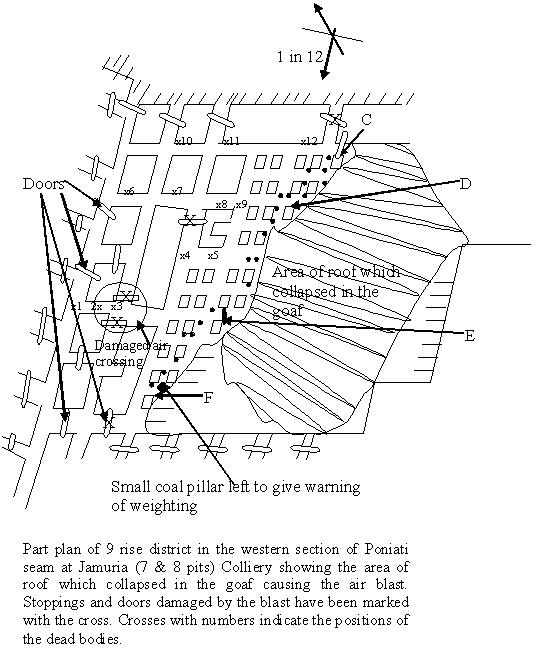

Air Blast: Jamuria Colliery Mining Accident on 08.10.1943The accident occurred in the Poniati seam which was 3.6 to 4.1 m thick at the colliery and was inclined at 1 in 12. The seam was overlain by coarse- grained massive sandstones, about 26 m thick. At the place of the accident the cover was about 137 m.

The workings were laid out in panels. During depillaring, each pillar was divided into 4 stooks by driving cross splits through the centre of the pillar. The stooks were then extracted starting from the goaf end. The accident occurred in the 9 Rise district in the West section. This district consisted of 32 pillars of which 23 pillars had already been extracted and of the remaining 9, seven had been split and extraction of 4 stooks, C, D, E and F, was in progress. As the seam was prone to spontaneous combustion, isolation stoppings had been constructed in all the entries except 4; two of these served as intake airways and the other two as return airways.

Air Blast: Jamuria Colliery Mining Accident on 08.10.1943

The roof in the entire goaf area, measuring about 120 m x 100 m, had been standing for so long. On 8.10.1943, just at the end of the second shift, it fell all of a sudden without any warning. The resulting air-blast was so strong that all the persons present in the district were blown off their feet. Almost all the isolation stoppings were damaged, most of the ventilation stoppings, doors, empty and loaded tubs were blown away and cogs and props were dislodged. Five persons were killed on the spot and eight received serious injuries of whom six died subsequently. Some died by concussion, others due to fractured skulls.

The management was fully aware of the possibility of a severe air blast. No roof fall had taken place even though 70% of the panel area had been extracted and therefore an air-blast was imminent when the roof fall eventually occurred. Therefore as a precaution they were leaving small stooks of coal measuring 1.2 m x 1.2 m and props of 7 to 10 cm diameter inside the goaf as extraction of pillars progressed. The idea was that the small stooks and the slender props would readily yield when “roof weighting” occurred, thereby giving a warning prior to the fall of the roof. These precautions would normally allow sufficient time for withdrawal of all persons to safe places. Five such stooks and a number of tell-tale props were left at various points in the goaf. Four of these stooks and a number of props were buried under the fall, and one stook and a few of the props were left standing undamaged in the uncollapsed part of the goaf adjoining the working places. The total absence of any warning of the impending collapse indicated that there was no “weighting” as would have normally happened and therefore the sudden fall must have been caused by some hidden slips in the roof.

The management had even provided vent holes of 0.9 m x 0.9 m in some of the isolation stoppings with a view to provide additional outlets for the expelled air so as to lessen the severity of the blast. The Chief Inspector of Mines was of the view that the management had taken adequate precautions against the danger arising from an air-blast and nothing more could have been done in the course of normal goafing operations.