Envis Centre, Ministry of Environment & Forest, Govt. of India

Printed Date: Wednesday, August 27, 2025

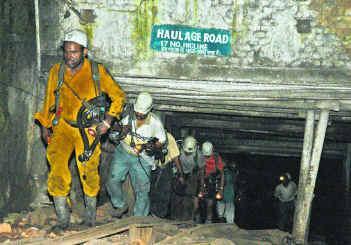

Bhatdih colliery on 06.09.2006

Bhatdih colliery

| Date of the Accident |

- 06.09.2006 |

| Number of persons killed |

- 50 |

| Owner |

- Bharat Coking Coal Ltd. |

| Place |

- Jharia Coalfield |

The rescue team members coming out of the Bhatdih colliery

BLACKENED by coal dust and charred beyond recognition – that was the state of the victims of an explosion in the Bhatdih Colliery in the Nagda sector of Dhanbad district, Jharkhand, when they were pulled out. The officials of Bharat Coking Coal Limited (BCCL), the government agency charged with running the Bhatdih colliery, could not identify the bodies and hence took to calling out the serial numbers of the mining lamps that were still attached to the bodies, and correlating the numbers with the attendance register. Heartbroken relatives walked up and confirmed their identities.

Fifty miners died in Mine on September 6 as a consequence of a methane explosion almost half a kilometre underground. The lethal combination of coal dust and carbon monoxide is believed to have killed those who survived the initial shock of the explosion. Only four workers on that shift escaped. They were haulage operators working at Level Zero, 400 feet (120 metres) below the surface.

The State machinery has swung into action – offering monetary compensation for the lives lost, jobs for the next of kin of the dead, and promises of inquiries that will submit reports in “the due course of time”. At present, officials from the Directorate-General of Mine Safety (DGMS) are unwilling to voice anything beyond their sincerest condolences. The immediate causes of the explosion are unknown.

What is known is that the explosion occurred at about 7-40 p.m., three and a half hours into the second shift of the day. Given the immense complexity of the operation, the immediate cause could have been anything.

As mines go, Bhatdih is a relic. Unlike the fully mechanised Moonidih Project and the partly mechanised Sudamdih Project (both in the Jharia coalfield in Jharkhand), almost every single process in Bhatdih is performed manually by a team of permanent and contract workers.

Every day, in three shifts of eight hours each, the mines at Bhatdih resonate with the sound of powerful explosions deep in the heart of the earth. Hundreds of miners strap on their mining lamps, secure their plastic hardhats and descend hundreds of metres into what they call “the womb of mother earth”. Blasted out of sheer rock, mud and rubble, the womb consists of a series of sharp gradients burrowing deeper and deeper into the earth, branching off into narrow secondary tunnels and terminating at fertile mining “faces” where coal is extracted off the walls using high-grade explosives.

“Right from drilling holes in the mine face to laying explosives, to collecting the recovered coal, to hauling it to the mainline, everything is done by hand,” says Amrit Lal, a worker at Bhatdih. “The only mechanied operation is the hauling of coal tubs from the mainline to the surface.”

Each mining team consists of a specific set of individuals with complementary skills. The overall functioning of the team is supervised by an overman and a mining “sardar” who evaluate the safety of the work area and check for the presence of highly inflammable methane and coal dust. The mining face is then sprayed with water to settle any suspended coal dust. The “driller” then bores a number of closely spaced 10-15 inch (25-35 centimetres) holes into the mining face, and the “short-firer” checks for any gas (methane) that might have been liberated and then fills the bores with explosives. A safety warning is sounded, and the mining face is blasted open. Water is sprayed once more, and then the “support gang” is called in.

Entrusted with securing the area of operation, support gangs are essential in labour-intensive mines such as Bhatdih. Support workers erect ad hoc beams, arches and pillars to guard against roof falls. They provide cover for teams of “loaders” to collect freed coal and fill it in one-tonne tubs. The tubs are then pushed along the narrow tortuous tunnels by teams of trammers, and hauled to the surface by haulage operators waiting by the mainline.

An explosion like the Bhatdih blast requires a highly inflammable substance that, on combustion, produces large volumes of hot gases almost instantly. It is a well-known fact that Bhatdih is a highly “gassy” mine, with a methane gas production of over 10 cubic metres a tonne of coal mined. In fact, it was classified as a “third degree gassy mine” by the DGMS, requiring special precautions to control the production and accumulation of methane. The magnitude of the blast suggests the sudden ignition of a large pocket of methane in an enclosed section of the mine. But how did it get there? What are the precautions that prevent such build-ups?

“Methane build-up is prevented by a number of precautions,” explains D.K. Srivastav, Deputy Chief Personnel, BCCL. The first step is ensuring that the mine is ventilated well using a powerful fan and a system of partitions to direct the blast. This ensures that gas is pushed out of the mine even as it is produced.

The second step is the use of safety lamps and methano-meters to check methane levels in workspaces so that workers can be evacuated in case of methane emergencies. The third and most crucial step is the “stowing” or blocking of used mining channels.

Once mined of their coal, passages in gassy mines must be blocked with a mixture of sand and water. “Gas forms in areas left vacant,” explains Srivastav, “which is why it is imperative to block all passage ways that are not in use.”

But were these precautions followed? Predictably, Srivastav has refused to comment before the inquiry reports are submitted. But workers interviewed by Frontline narrated a shocking story of managerial neglect.

“We haven’t stowed a bunker for almost three months,” states a worker speaking on condition of anonymity. “The mine has been getting hotter and hotter by the day, but no one seems concerned.” According to the workers, the management simply engineers a roof fall at the entry of the passages and seals it with sand. The rest of the tunnel is left empty to accumulate methane. This accumulation caused by incomplete stowing could be a primary cause for methane accumulation and the September 6 explosion.

Early reports in the media suggested that the explosion could have been triggered when a mine face was blasted in a methane-rich environment. However, new information suggests that the explosion occurred before the crew set the charges on the mine face. Intact electrical wiring (used for blasting) found near the site of the explosion bolsters this theory.

“The blast must have been caused by electrical sparking,” suggests Adalat Deswali, president of the Bihar Colliery Kamgar Union (BCKU), a local union affiliated to the Centre of Indian Trade Unions (CITU). “This is very possible given that the wiring in the mine has not been upgraded for the past 30 years.”

Another factor that might have contributed to the blast could be the presence of large amounts of coal dust in the air. The large active surface area of a coal-air suspension makes it a lethal explosive. In most mines, water is sprayed at regular intervals to make this dust settle and thereby reduce the risks of fires. In Bhatdih, by contrast, workers were forced to make do with a bucket or two of water for spraying operations. Thus, once the electric spark was ignited, it found ready fuel in the form of methane and coal dust.

What is surprising is that the accident did not occur earlier. Workers allege that three months ago the management changed the explosive used in the mines. “Earlier we used Powergel 501 for blasting in the mines,” said a worker speaking on condition of anonymity. “But that was replaced with Super Coal-5 three months ago.”

A quick perusal of the list of approved equipment on the DGMS website reveals that while Powergel 501 can safely be used in one-, two- and three-degree gassy mines, Super Coal-5 is meant solely for one- and two-degree mines and is unsafe for three-degree mines. To sum up, the mines at the Bhatdih colliery were using the wrong explosives in a poorly ventilated, badly stowed, third-degree gassy mine filled with coal dust-laden air. An accident like this one was waiting to happen.

So how does one improve mine safety? Senior technical officers at the BBCL told Frontline that increased mechanisation was one way of reducing accidents. Mechanisation would also reduce the occurrence of roof falls – the most frequent of mining accidents.

Using machines such as coal shearers or “continuous miners” obviates the need for blasting and thus contributes to a safer working condition.

Unfortunately, mechanisation is often spoken of alongside the need for privatisation of India’s coalfields – a link that is not as obvious as its supporters claim it is. The argument used is that private money shall improve worker conditions and increase safety – yet projects such as the Moonidih mine illustrate that mechanisation and improved worker safety is possible in professionally run, government-owned mines too.

The past 10 years have seen increased private participation in mines in eastern India – particularly in opencast mines in West Bengal. The Sarisatali Coal Mine Project in Asansol, West Bengal, is a large opencast coal-mining project that has been leased out to two private contractors – Integrated Coal Mines Limited (ICML), owned by the Goenka Group, and the Eastern Minerals and Trading Agency. Roop Kumar Sandhu, joint secretary of the ICML Samik Union, explains that while ICML acquired the area in 1998, the mine was sub-leased to G.S. Atwal, a Kolkata based company. Atwal has further sub-contracted out the majority of its work to a number of contractors such as Shiny Transport Limited.

Officially the mine employs about 900 workers, but the actual figures are close to 1,200. Of these, only 80 workers actually have permanent jobs as they were title-deed holders of the land acquired by the company for the mine. This has made collective negotiation difficult as troublesome workers are simply fired without notice.

Further, sub-contractors are held responsible for the welfare of their workers and so the holding company – say, Atwal or ICML – cannot be held legally responsible for the welfare of contract workers. Only registered workers of Atwal or ICML are eligible for provident fund, medical expenses, housing and so on.

It is tempting to suggest that greater unionisation would help solve many of the problems of the mining industry, and there is much to be said in favour of collective bargaining. However, unions in West Bengal are inextricably linked to the ruling party and so have a tendency to side with policies of the State government with mixed results for the workers that they represent.

The mine disaster represents a rupture in the seamless narrative of the market, state and the media where growing demand for energy is synonymous with a growing global economic clout. The disaster emerges as a ghost that must be exorcised immediately in the larger interests of the nation.

“This is a war as important and dangerous as Kargil,” observed D.K. Srivastav in a belated attempt to build worker morale. The workers smile wearily.